We all know that chainsaws should cut smoothly and make nice straight cuts on any angle that we choose, whether on a down-cut or an up-cut. However, as we also know, sometimes they don't.

Identifying the Problem

When a chainsaw cut tends to pull to one side or the other, or is making a curved cut as it progresses downwards, it will usually stop cutting fairly quickly unless the bar is withdrawn and realigned, and the bar can often jam in the cut. It can also make it problematic to properly line up undercuts, and in general makes it very difficult to get an otherwise routine cutting job completed effectively. Even professional saw users can experienced this issue to some degree, and it is very frustrating whatever your skill level.

Identifying the Problem

When a chainsaw cut tends to pull to one side or the other, or is making a curved cut as it progresses downwards, it will usually stop cutting fairly quickly unless the bar is withdrawn and realigned, and the bar can often jam in the cut. It can also make it problematic to properly line up undercuts, and in general makes it very difficult to get an otherwise routine cutting job completed effectively. Even professional saw users can experienced this issue to some degree, and it is very frustrating whatever your skill level.

When a chainsaw won't cut straight many users will look at the chain-bar as the faulty component. It seems logical that a bent bar may cause this problem, because it is the bar that guides the chain through the log. If a bend is indeed evident in the bar, it would be reasonable to assume that the problem has been identified. In this case some will straighten the bar, others may replace it. Unfortunately for most, the saw's cuts will usually still pull in the same direction after the repair.

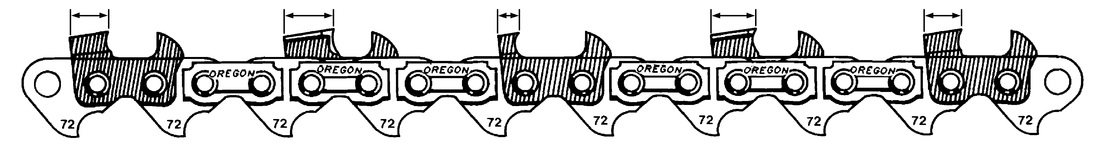

This is because, when a chainsaw won't cut straight & cleanly through the log it's usually the chain that's the culprit in most cases. The example below shows top plates (teeth) that have become unequal over a series of sharpenings. This causes each tooth to take a different sized bite of wood. Since a saw chain is a "team" of cutter teeth, the cut will pull in the direction of the side whose cutter teeth take the biggest bites. It is as simple as that.

Sharp On One Side - Dull On The Other

All cutter teeth should be sharp, filed at the correct angle, and be the same length. Usually this is easier to accomplish with a grinder than it is with a file. When hand filing, this must be done by eye. On a grinder, the angle, depth, and length can all be preset. This makes it easier to duplicate each cutter tooth. When filing, it is more difficult. Those of us who are right-handed often do a good job sharpening the left side cutters, yet find in more difficult to sharpen those on the right side. Those who are left-handed have the opposite experience. After several filings, a chain will usually show the effects of this. Teeth on the side easiest to file are usually sharper but shorter. The other side has longer teeth, but may remain dull even after filing.

People who use the proprietary grinder-sharpeners are not immune to producing inaccuracies in chains & teeth, although the results are usually markedly better than file sharpening. Adjustments on the grinder set-up must be checked occasionally to be sure that ALL the unevenness is being removed from ALL the cutter teeth and that the chain is nicely symmetrical on both sides. This is particularly important when you are grinding a chain which has been hand sharpened a few times with a file. It is also necessary to check to be sure that all top-plates of the individual teeth are equal in length. Grinders are great, but they do not make you completely infallible.

Pulling or Curving Problems Which Are Hard To Diagnose

Some curving & pulling problems are hard to diagnose - even for experienced saw users . Occasionally, cut "pulling" or "curving" problems may indeed be caused by a bad bar plate or perhaps even a tightening bolt/nut that sticks out a little too far. A colleague experienced this problem with one of his new saws. He puts on a new chain, and after a few cuts his cuts start to curve. Chain after chain, this would repeat itself over and over.

What he found was that at a particular speed and/or angle the chain would lightly touch the bar tightening bolt/nut. The contact of the teeth on the bolt, even though slight, would be just enough to dull the corners of the cutters on one side of the chain. Since the other side would be still sharp, the cut starts to curve or pull in the direction of the sharp cutters. He rectified the problem by switching chains to one with a slightly different cutter profile which, even though the difference was only millimeters, was sufficient to eliminate the problem.

Some Advice

When your chainsaw cuts or curves unevenly to one side or another or simply sits there in the kerf without cutting, take a careful look at the cutter teeth on the chain before you spend money on anything else. The condition of the chain and teeth will usually be the problem.

RSS Feed

RSS Feed